Through a competitive tender process, Marafiq selected Tunisian EPC contractor Engineering Procurement & Project Management (EPPM) to deliver a HYBACS solution for their current capacity shortfall. Once completed, the HYBACS process will deliver an approximate 150% uplift in capacity, treating 50 MLD of industrial wastewater from the city.

IWTP-8 comprises three parallel and separate treatment streams to treat industrial wastewater arising from the large industrial cluster in Jubail.

Stream 2 includes a 3-lane activated sludge process with 8 circular clarifiers and currently treats around 20,000 m3/day. The HYBACS upgrade will increase treatment capacity to 50,000 m3/day.

The client’s specifications for the upgrade include that the existing treatment process must not be interrupted during the upgrade, the solution must be a proven technology, be highly energy efficient, have a small footprint and that the upgrade must be completed within a short timescale.

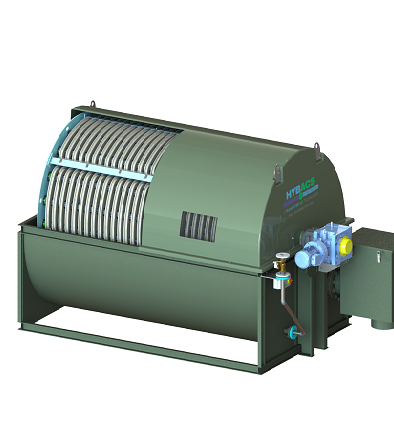

The upgrade at IWTP-8 will include the installation of 16 SMART™ Units as well as capacity upgrades to the tertiary treatment stages. SMART™ units are high-rate bioreactors that, when installed upstream of the existing aeration lanes, form Bluewater Bio’s proprietary HYBACS – HYBrid ACtivated Sludge – process.

The primary settled wastewater and return activated sludge (RAS) will pass through the SMART units then into the three aeration lanes. The SMART units accelerate the rate of hydrolysis, enabling the plant to accept a higher load. They also provide a very high floc loading and enhance the settleability of the sludge, enabling the existing settlement tanks to accept higher flows.

Bluewater Bio’s scope will include, in addition to the supply of the company’s proprietary SMART units, process design, installation supervision and service and maintenance for the units. EPPM, in their role as Lead Contractor, will carry out all civil works construction as well as enabling works design for Civil and MEICA.

Fergus Rooksby, Commercial Director of Bluewater Bio, commented:

“We look forward to working with EPPM and Marafiq in delivering our HYBACS process to help alleviate overloading at the IWTP-8. This contract will be our first HYBACS installation in the Kingdom of Saudi Arabia and marks a significant milestone in our Gulf expansion plans, building on our award-winning 100 MLD HYBACS plant at Tubli WPCC, Bahrain.”

HYBACS augments the widely-implemented activated sludge process, with the core benefit being that it enables an existing activated sludge plant to be rapidly upgraded for increased capacity and/or performance, by simple offline installation of SMART Units.

Fergus Rooksby continued:

“With over 5 years’ worth of highly compelling data from our HYBACS plant in Bahrain, meeting and exceeding the challenging discharge consents, Bluewater Bio is well positioned to capture a significant proportion of projects requiring an uplift in capacity or tighter discharge consents across both the Kingdom and the wider Gulf region.

“HYBACS’ ease of implementation and maintenance, coupled with significant savings in operating costs and hence total cost of ownership over the lifetime of the plant, makes for a compelling solution to a common problem encountered by utility and industrial operators alike.”